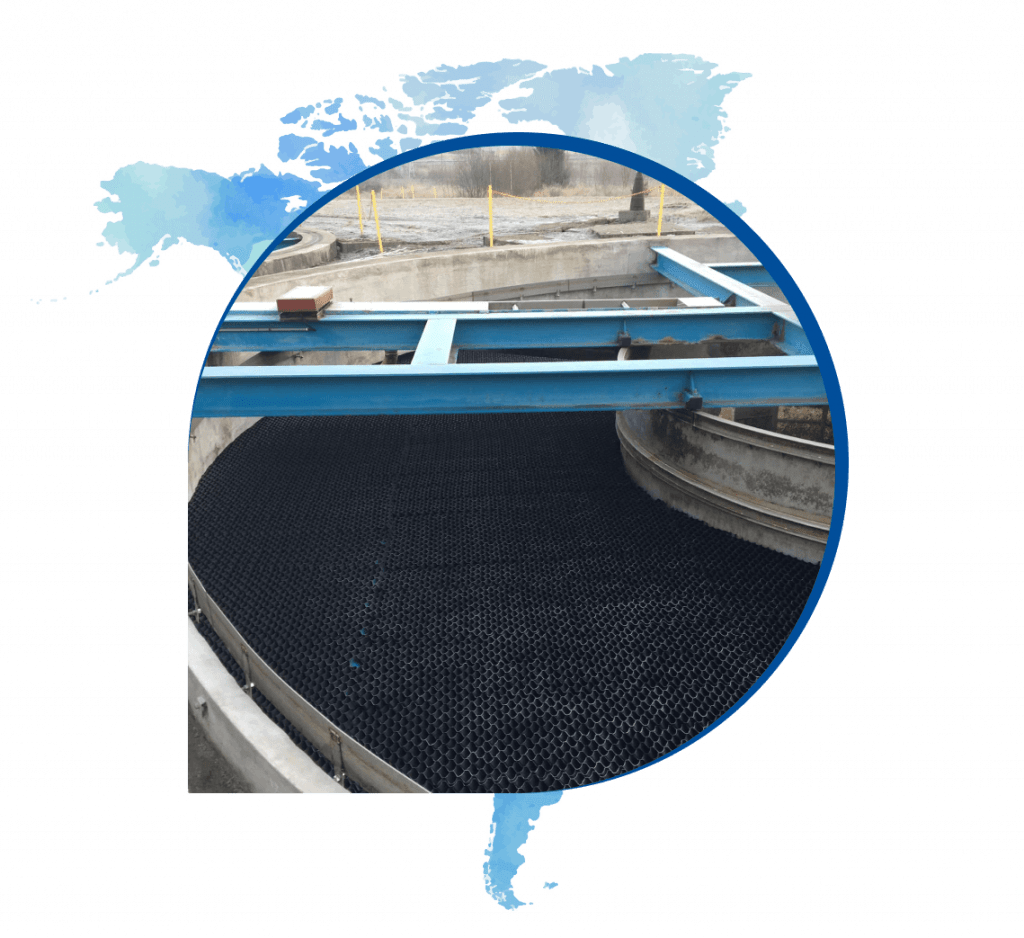

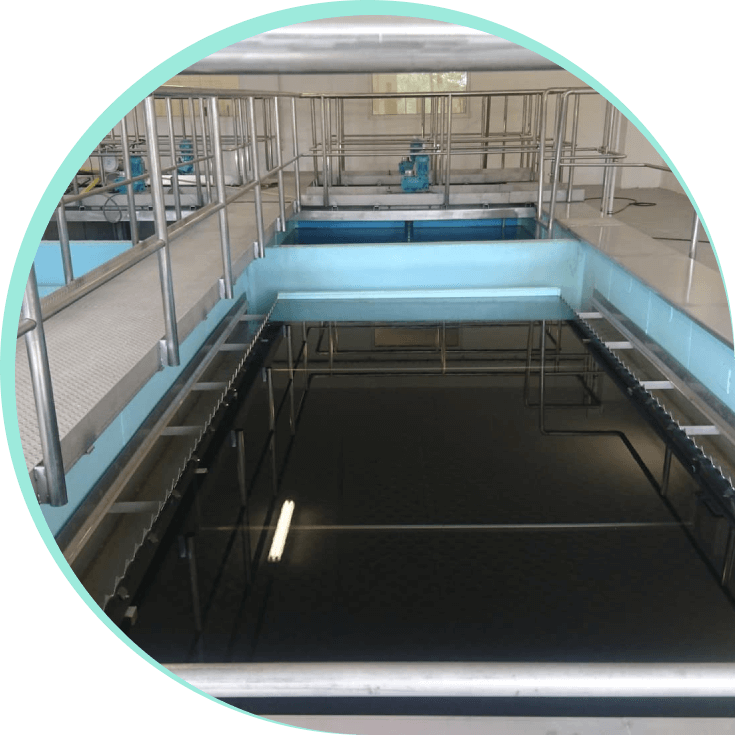

The technology of sedimentation and water clarification is used in the purification and treatment of industrial water in the energy industry, as well as in the purification of industrial wastewater, the post-purification of municipal wastewater and the treatment of drinking water. Essentially, the application is common for municipal and industrial wastewater purification plants as well as for water treatment plants.

Purification and treatment of industrial waters in the energy industry

Production and treatment of drinking water

Post-purification of municipal wastewater

Industrial wastewater purification

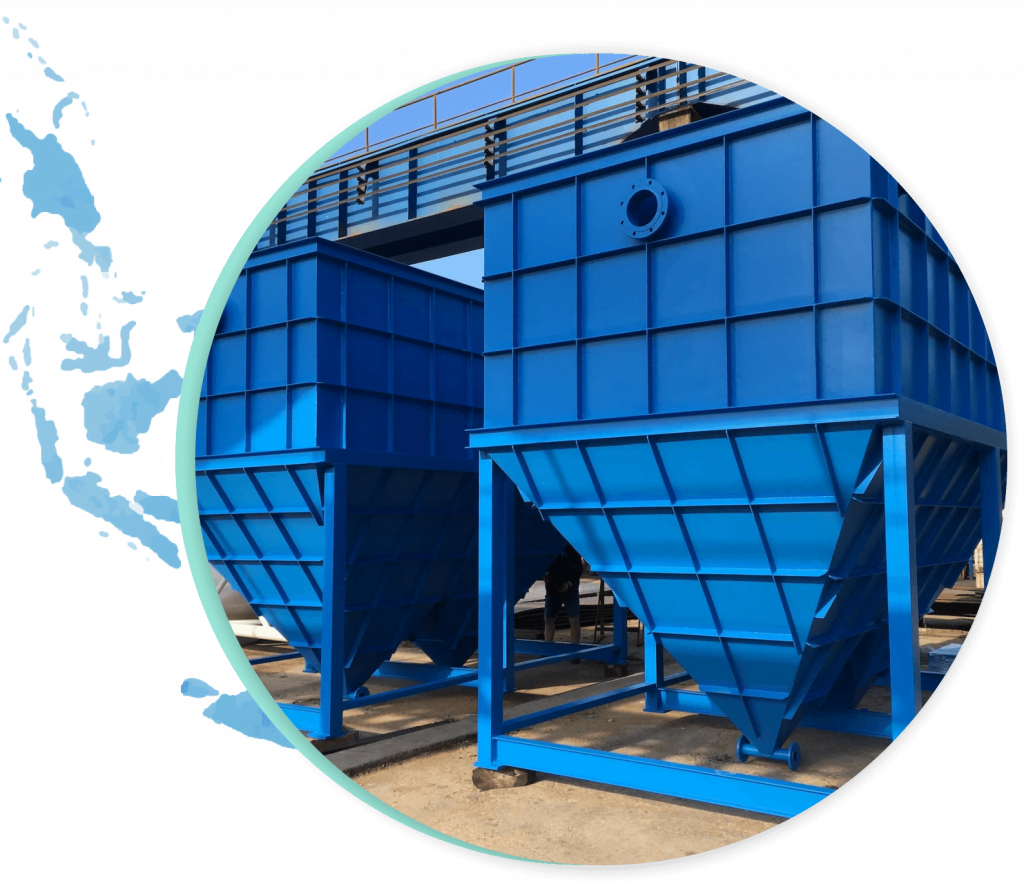

We produce equipment for sedimentation and water clarification in several designs, which we can customize for you. Our services include equipment transport, technology installation, and operator training. Warranty and post-warranty service is a matter of course. Also see our other technologies including sludge thickeners, precipitation reaction technologies, and sludge extraction equipment.

We supply technologies for sedimentation and clarification to Finland, Poland, the USA, and Africa. Get inspiration from the product application at our customers. Check out the selected references.

Are you looking for filtration technologies for industrial or municipal wastewater? Write us an email. In ENVITES, spol. s r.o. we are specialists in the design and production of wastewater purification equipment. We will find suitable custom-made solutions for you.