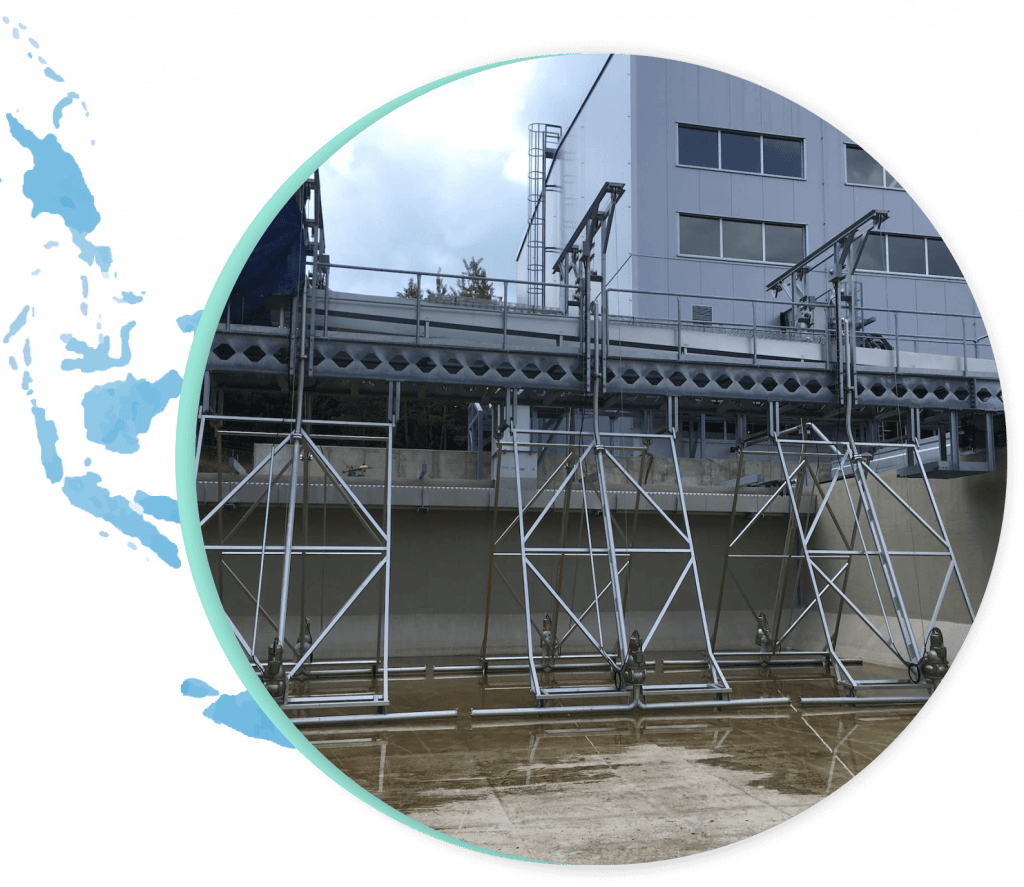

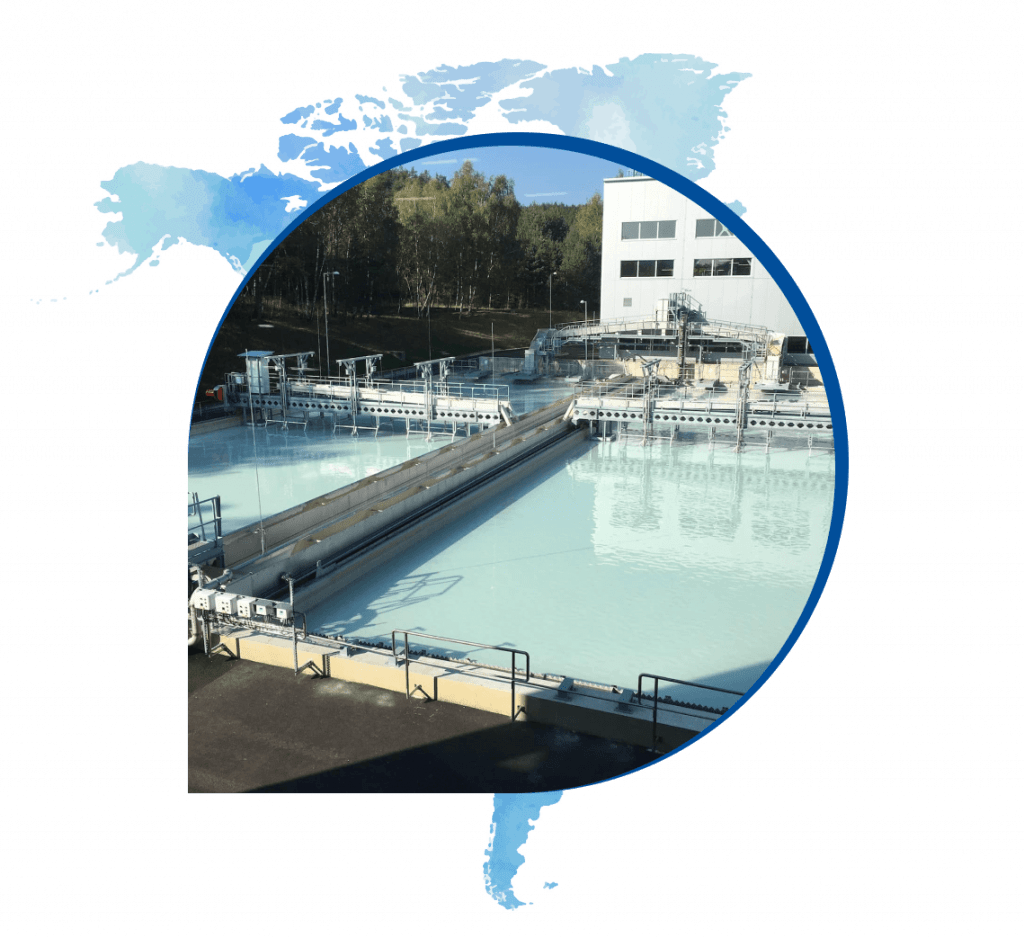

We design, produce, and deliver turnkey technological built-in segments for new or existing tanks. Tanks can be concrete or steel. Built-in technologies increase the efficiency of the process, whether it is the removal of sedimenting impurities or the scraping of sludge at the bottom of the tank. We also replace old inflow and outflow parts of existing tanks.

Production and treatment of industrial and drinking water

Municipal wastewater purification

Industrial wastewater purification

We will custom-make the equipment for extracting and scraping the sludge for you and deliver it including transport and installation. We are also happy to supply precipitation reaction technologies, chemical preparation equipment, and tiltable containers for waste cake collection to you.

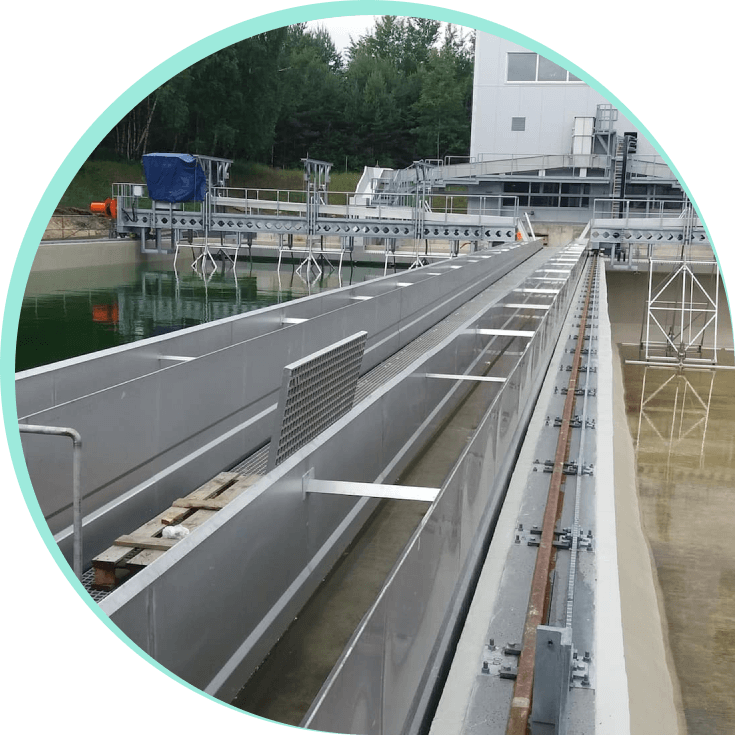

We design and produce professional technologies for wastewater purification plants in Brno and deliver them all over the world – Scandinavia, North America, the Balkans, and Africa. Check out our selected references.

Do you wish to receive more information? Send us an email with your request. We will recommend you an effective and at the same time economical solution for the extraction and scraping of sludge from tanks. At the same time, we will give you expert advice in the field of wastewater and industrial water purification.